Event Technology & Production Materials

Content

1. Overview and problem statement

Did you know…?

Fifty-five percent of global greenhouse gas emissions occur in the energy sector, and the remaining 45% through the manner in which we manufacture and use products today? 53 In addition to switching to renewable energy, we thus need a circular economy using materially healthy and reusable products, in order to achieve the Paris climate goals.54

For festivals and large concerts, an immense quantity of material is used and installed. This isn’t merely cable binders and duct tape, but also stage material, railings, sound- and lighting systems etc. Only a small portion of these materials are today recyclable using Cradle to Cradle principles. The majority of products cannot be completely recycled and often contain substances that are harmful to the environment as well as humans.55

For infrastructural components like tents, stages and crowd barriers, it is difficult for event organizers to directly influence the materials used. However, a circular business model like renting or leasing can ensure such components are reused as long as possible.

Another consideration is the disposal of materials onsite. There are partially sustainable alternatives for products like cable binders and tape. However, the necessary collection- and separation systems have not been widely established.

Whenever possible, consider using production materials that contain no toxic substances and are capable of recycling as well as being rented and used for many years. If alternative materials are used, service providers should be informed about their use and disposal. In general, the organizer can influence the quality of the materials in cooperation with the manufacturer; however, this is the exception in the event industry as of now.

2. Our Benchmark for Tempelhof Lab

At Tempelhof Lab, we tried to use as many C2C products as possible and initiate new projects:

- We focused on what we can influence locally. As the concerts were part of a larger tour, we had limited influence on materials used by the bands and their crews. Certain production materials like staging, PA and lighting systems were already booked, as was the decision on how to transport them to Tempelhof Lab.

- For the materials we could influence, we attempted to use C2C quality. Alternatively, sustainable products should be used whenever possible.

- Through the project and the discussions with manufacturers, we aim to draw attention to recyclable materials and the C2C concept.

- Focus on renting equipment, recyclable and sustainable products when possible. Purchasing new products should be the alternative only where necessary.

- Extensive separation and waste disposal system for one-time use materials and ensure subsequent recycling.

3. What worked well, what can be improved?

For Tempelhof Lab, we took various measures to use materially healthy and recyclable products.

Stage

What worked well?

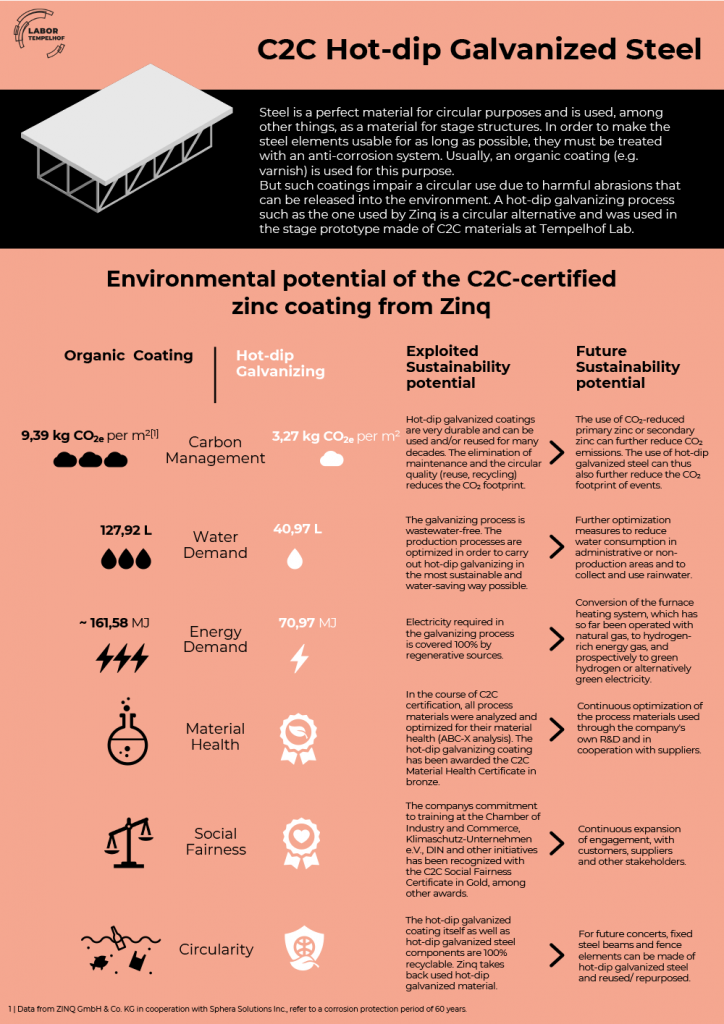

- Pilot project: Prototype of a modular C2C-stage, which after a long period of use can be dismantled into individual parts and recycled separately. For that purpose, a C2C-certified fire galvanized steel and a C2C- certified paneling (wood and recycled plastic) were used.

- Information about the material used for the stage- prototype was stored in a digital material passport. It gives an overview of the quality and quantity of all used materials, where and how they would be installed and in which manner the materials can be reused for a new product. 56

What can be improved?

- The goal was to construct one of two raised platforms for people with disabilities from C2C materials as a field test. There was insufficient time for the safety- and acceptance processes to implement this.

Loud speaker system, lighting and lamps:

What worked well?

- For an educational project, we displayed a PA system in the “Cradle Village” that goes back to the manufacturer after use, to be refurbished and returned to the market –an example of how circular business models can support a circular economy.

- Use of 100% LED technology and no pyrotechnics, confetti or CO₂ streamers at Die Ärzte concerts.

What can be improved?

- Use of tried and tested, certified and reused PA- systems and loud speakers not only as an educational project, but even on the main stage. For Tempelhof Lab, this was not possible because the bands already had contracts in place for tour equipment.

Other production materials:

What worked well?

- Recyclable textiles for use on stages (B1 approved) as exhibition pieces in the “Cradle Village.” This molton would be scalable for a large event without any problem.

- Informational materials like banners and posters were displayed, if possible, from C2C materials. Alternative sustainable materials like PVC-free banners were used. We rented many of these items or produced them ourselves, instead of buying them.

- C2C chair made of recycled wood and C2C-certified seat covers for the use backstage.

What can be improved?

- Reusable cable binders: For practical reasons, these could not be used due to the size of the event.

- In general, to ensure the use of materially healthy products, plan well in advance and discuss with manufacturers.

4. Findings and Recommendations

- Use market power

- The bigger an event, a venue or an artist is, the greater influence over the quality of the production materials requested from material or service providers. Using your market power to discuss materials and set/request a certain quality standard can be a great lever to change industries.

- Set priorities: Which material is used in high volumes and/or is particularly harmful to the environment? Place particular emphasis on recyclability for those materials.

- Plan time

- To construct a large stage from 100% C2C materials requires cooperation with the service provider and must be planned many years in advance. The required materials of C2C quality are currently available on the market.

- Even for smaller products, the search for alternative, toxin-free materials is very time-consuming and should be considered in project planning.

- Field-tested circular business models already exist and can be further developed.

- Renting different products is a step towards more recycling capability and longer use of materials. This is already standard practice for medium and larger production materials. Purchasing such items should no longer be considered.

- In discussion with service providers or manufacturers, joint projects for circular business models for as-yet unavailable products can be implemented, such as the case of adhesive tapes.

- In our case, the concerts were part of tours for which numerous contracts had already been signed. This gave us limited room to maneuver, especially for production materials organized on the tour side.

5. Service Provider Contacts

6. Further inspiration from the industry

The DGTL festival (capacity: 20,000) aligns its circular actions according to the 7 R- Principle: Rethink, Reject, Reduce, Repurpose, Reuse, Recycle, and Compost. Applying this principle, the festival achieved 0 grams of waste per person per day for the first time in 2022. Core elements are: deposit mugs made of hard plastic and a large-scale communication campaign to raise public awareness about waste reduction. Materials are collected in mesh bins instead of trash cans for visibility. In addition, the festival earns money from the residual waste generated, by reselling cans and clean mono-flow PET to processors that make new products from it. Through modular stage construction and the efforts of the local production crew, construction waste has been reduced by 86%, and any materials used are publicly displayed in the form of a flow analysis. 57