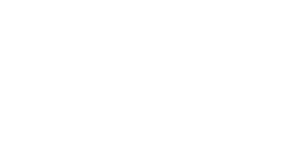

1. Overview and problem statement

Did you know…?

Much of our clothing is produced in poor working conditions. 80% of people in the textile industry are women and girls, who work on average over 60 hours per week for less than 18 cents per hour and come in contact with toxic chemicals. In addition, a conventionally produced cotton T-Shirt requires more than 2,000 liters of water in the manufacturing process. 49

According to the EU, the textile industry is one of the most harmful industries worldwide – starting with the cultivation and mining of raw materials, through production and working conditions and the use of inappropriate materials, up to consumption. In the event industry, textiles are not only used for clothing, like merchandise or work clothing, but also as carpets or upholstery in the theater. Thus, the industry has the challenge to produce a quality of textiles that does not harm humans or the environment.

The challenge of merchandise production for events lies in the supply chain. Ideally, merchandise must be available for quick delivery and replenishment, given limited warehouse capacity and the need to pre-finance merchandise.

For event organizers and bands, merchandise is an important financial source and marketing tool that must not be at the expense of other people and the environment. A paradigm shift and taking responsibility for one’s own actions are necessary.

2. Our Benchmark for Tempelhof Lab

The aim with Tempelhof Lab was, both for merchandise as well as in case of production textiles and work clothing, to use fairly produced, sustainable products meeting Cradle to Cradle criteria.

- Ideally, all textiles used are of Cradle to Cradle quality.

- Alternatively, certifications such as Fairtrade, GOTS or other certificates recognized by the Green Button that also ensure compliance with human rights along the supply chains.

- Precise planning of demand and limited quantities to prevent overproduction.

- Optimally regional production and short transport routes.

- Use materially healthy inks and recyclable materials.

- Use merchandise T-shirts to educate the public how materials can be recycled in the textile industry.

- No individual packaging of merchandise and textiles and choose fully recyclable packaging.

- For all merchandise, consider whether it is really necessary (lighters, glow sticks, etc.) and to what extent there are Cradle to Cradle quality alternatives.

- In the case of merchandise cups (with imprints for the tour issued in the catering area), use reusable products that are healthy in terms of materials..

3. What worked well, what can be improved?

In case of Tempelhof Lab various measures were taken to justify the theme fair, sustainable and recyclable merchandise:

What worked well?

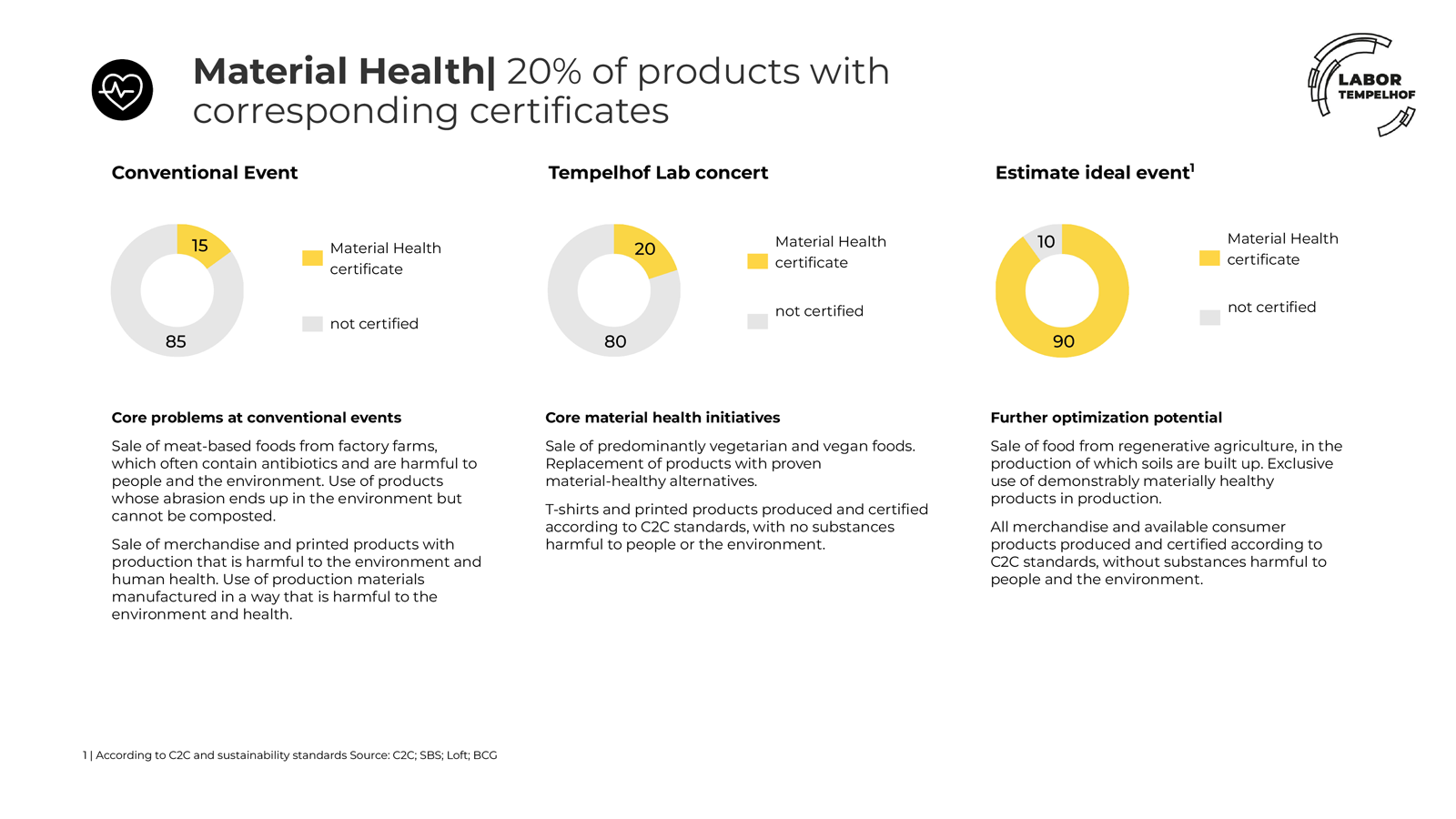

- 20,000 C2C-certified T-shirts were produced for Die Ärzte and Die Toten Hosen. These organic cotton T-shirts are manufactured with renewable energy and nontoxic ink. The fibers can be reused and are biodegradable. To date, this was the largest single production of C2C- certified merchandise in Europe.

- Create a traceable supply chain for merch T-Shirts, provided in the form of a QR- code, so that the delivery chain of the product is transparent to the consumer. 50

- Remaining merchandise from Die Ärzte and Die Toten Hosen are GOTS certified and made from recyclable natural fibers like organic cotton.

- Merchandise mugs for the public are reusable.

- Educational project: recyclable stage drapery (B1-Molton) in the “Cradle Village”.

What can be improved?

- Any merchandise- textiles are made completely of C2C- certified materials. At Tempelhof Lab, this was impossible due to longer production timeframes required for this quality of product and delivery chain difficulties caused by the pandemic.

- Also use material-healthy printing ink for the reusable merchandise cups.

4. Findings and Recommendations

- C2C-certified merchandise-T-shirts are still the exception today. Offering 100% C2C- certified merchandise presents many challenges.

- Longer production times are required. C2C printing procedure needs more time than the traditional printing procedure, since the printing paste is processed in a different manner.

- Make people aware of the additional time and financial effort involved in implementing C2C merchandise. There are different suppliers of C2C-certified T-shirts at very different price points. At Tempelhof Lab, we were in discussion with suppliers whose unprinted merchandise was between 0.5 and 12 times more expensive than a T-shirt according to the GOTS standard and conventional ink. In the end, the additional costs for the finished printed shirt were threefold.

- Explaining the circularity of a C2C T-shirt and the traceability of the supply chain via QR code are easy to implement and help raise awareness of how the textile industry as a whole can be changed.

- The larger the print run, the cheaper the price. With greater demand, event organizers, merchandisers and artists can contribute to structurally changing the textile industry.

5. Service Provider Contacts

6. Further inspiration from the industry

Other events and artists are also looking at sustainable merchandise:

Milky Chance is rethinking merchandise in collaboration with merchandise provider Sustain. Fans can have their own T-shirts screen-printed onsite at concerts. This counteracts the manufacturing of new clothing while giving fans a special, limited edition design that is only available locally. Thus, there is second-hand merch at every Milky Chance concert. 51

The 1975 also recycled merchandise at their Leeds/Reading Festival gigs and screen-printed it on site: fans brought old 1975 T-shirts from home and received an updated design on site for free. Old merchandise from the band’s warehouse was also reprinted onsite. 52